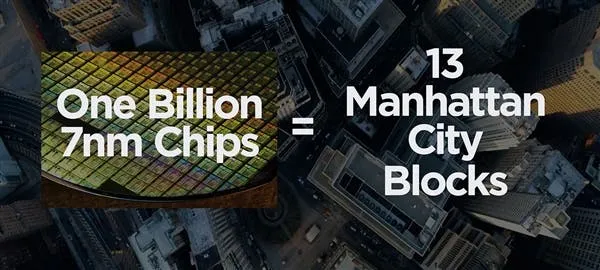

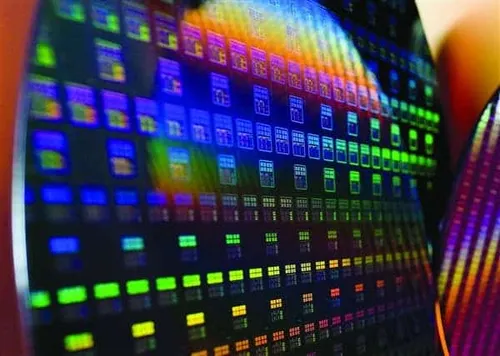

A few days ago, TSMC announced on its official blog that in July of this year, TSMC produced its 1 billionth functional and defect-free 7nm chip. This is a new production milestone for the company. According to TSMC, the 7nm mass production commenced in April 2018. Presently, it is serving over a dozen customers around the world and created more than 100 chip products. According to TSMC’s data, the first batch of 7nm products includes Bitmain’s mining machine chips, Xilinx FPGA chips, Apple A12, Huawei Kirin 980, etc.

Each 7nm chip from TSMC integrates at least 1 billion transistors. This means that so from the perspective of transistors, the cumulative scale of each chip exceeds tens of billions. As of now, TSMC's 7nm process is the fastest generation with the fastest increase in production capacity.

In chip production, issues of defects are quite common. You can only eliminate these issues by continuous production. TSMC has produced so many 7nm chips that it does not have to worry about defects any more. At this point, TSMC believes that its advantages surpass other semiconductor manufacturers.

The Taiwanese manufacturer also revealed that it is the first to introduce EUV (Extreme Ultraviolet Lithography) technology into 7nm commercial production. This is a very important stepping stone to the production of the 5nm process.

Today, 7nm is also applicable in the field of auto-driving cars with extremely demanding safety requirements. In addition, TSMC pointed out that an improved version of 6nm (N6) based on 7nm has also been introduced into mass production, and the transistor density has increased by nearly 20%

Loading