All major smartphone manufacturers understand that they rely on hardware and software makers. Huawei is the best example how a company can suffer if it doesn’t (can’t) cooperate with the top companies. That’s why they are gradually switching to a strategy of making “everything” themselves. Xiaomi and Huawei have already begun designing their chips and software, respectively. The next big name in this field is VIVO. We have been talking about the VIVO V1 imaging chip for a while. And today, following the schedule, the company took wraps off its ISP.

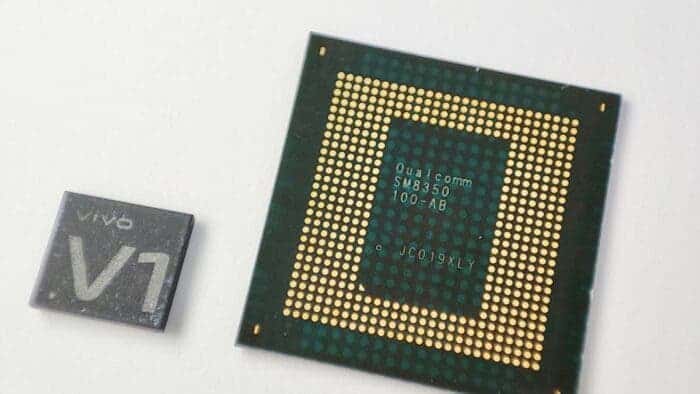

The VIVO V1 is the first professional imaging chip independently developed by the company. It opens the era of mobile phone hardware-level algorithms.

At the event, VIVO also talked about its achievements in the mobile phone imaging technology, such as ultra-high transparent glass lens, new coating technology, and Zeiss natural color. Through comprehensive collaboration with Zeiss in imaging chips, optics, and software algorithms, VIVO has greatly improved the night shooting experience.

First Independently-Developed Imaging Chip – VIVO V1

As the company said, they had an in-depth cooperation with mobile phone SoC manufacturers. It lasted 24 months. There have been over 300 people in research and development.

As a fully customized integrated chip with special specifications, the VIVO V1 cooperates with the main chip to provide compatible effects and experience. It also boasts of high computing power, low latency, and low power consumption.

The VIVO V1 can not only process complex calculations at high speed like CPU, but also complete parallel processing of data like GPU and DSP. Faced with a large number of complex calculations, the VIVO V1 has an exponential improvement in energy efficiency ratio compared to DSP and CPU.

In order to maximize its simultaneous processing capacity, VIVO optimizes the data storage architecture and high-speed read and write circuits inside the chip to achieve an equivalent 32MB large cache. It surpasses some of the current flagship desktop computer processors to achieve low-latency real-time noise reduction and frame insertion.

In addition, the calculation imaging algorithm in the VIVO V1 is superimposed. When processing tasks with the same amount of calculation at high speed, compared to the way of software implementation, the dedicated algorithm reduces the power consumption of the hardware circuit by 50%.

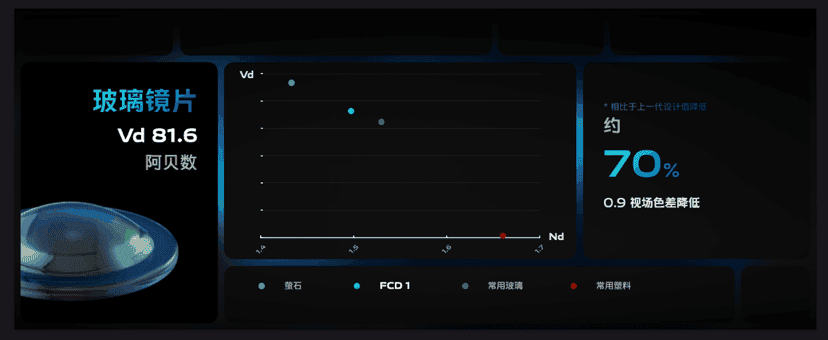

Ultra-low dispersion and high-transmittance glass lens

Because of space constraints, it is more difficult to achieve a further leap in taking pictures with mobile phones, and to upgrade the lens. So VIVO has invested a lot in research and development. After multiple rounds of verification with the Zeiss team, it finally overcame the technical limitations such as process and yield. Later, it realized high-spec glass lenses on mobile phones, achieving high light transmittance, ultra-low dispersion, and strong effect of thermal stability. All these greatly reduce the appearance of flare ghosts when shooting night scenes.

Compared with plastic lenses, glass lenses have a natural advantage of low dispersion. VIVO’s ultra-low-dispersion and high-transmittance glass lenses further reduce chromatic dispersion. In the Abbe number (an authoritative indicator for measuring chromatic dispersion), it has achieved the industry’s highest score of 81.6. This breaks through the Abbe number of mobile phone lenses. It is comparable to professional camera lenses.

The ultra-low dispersion and high-transmittance glass lens also achieves a higher degree of purity. The central transmittance is increased to a maximum of 95%. Also, it adopts an AOA dynamic optical calibration process to adjust the sharpness reduction caused by lens thickness error and lens eccentricity error to ensure the optical quality of the final lens.

Multiple coatings to suppress glare and ghosting

Since its inception, Zeiss T* coating has always been Zeiss’s strong guarantee for high-quality imaging. Thanks to this, VIVO and Zeiss have joined hands to apply advanced coating technology to mobile phone lenses.

Facing traditional industry problems such as glare and ghosting, VIVO introduced SWC coating technology. Based on the principle of bionics, the reflected light is fully suppressed, and the reflectance is reduced to a minimum of 0.1%, which greatly improves the purity. In addition, VIVO exclusively launched the ALD atomic layer deposition process to form a nano-scale coating on the ultra-high-transmittance glass lens to further reduce light reflection.

The problem of petal ghosting is also the shadow that cannot be shaken off by mobile phones. VIVO uses pigment spin coating technology in the lens to solve the problem of adhesion between pigment and blue glass. The coating thickness is as thin as 2um. After more than 10 different process parameter adjustments, VIVO has finally realized mass production.

Follow Gizchina.com on Google News for news and updates in the technology sector.