In September last year, Elon Musk announced that Tesla would smelt lithium ore in the United States. The target is to produce battery-grade lithium hydroxide. According to a recent report from AutoEvolution, Tesla has started a large-scale construction project on a construction site in Corpus Christi, Texas, USA. Most importantly, there is a sign beside the dirt road announcing that Tesla will build the first lithium (Li) refinery in the United States on the site. While Musk is known for his flamboyant personal style, he was uncharacteristically low-key in this case.

Reports from last year claim that work on this project will start as early as the fourth quarter of 2022. There are also rumours that commercial production would not be possible until the fourth quarter of 2024. Tesla previously explained to Texas regulators that it plans to build a battery-grade Li hydroxide refinery near Corpus Christi. Tesla’s report reveals that the plant will be to process the ore raw material into products more suitable for production.

Before that, Musk also tweeted that Li batteries are the new oil, affirming the value of Li in the modern economy. In addition, he also urged investors to enter the Li refining business in Tesla’s earnings conference call in July last year. He claims that the competition for Li cannot be lost. In fact, he even believes that this business is as good as printing money.

Tesla has previously stated that it plans to invest approx. $375 million in the Li refinery. The plant will employ about 165 full-time staff and another 250 contract staff. The contract will last for a period of about two years. The factory is expected to open in the fourth quarter of 2024 and be put into operation.

Tesla Li plant to use new processes

Tesla also claims that it will not use the regular process in Li handling. The company claims that in converting Li concentrate to battery-grade Li Hydroxide, it will use a new and “innovative process”. The new smelting plant will use a process that requires less harmful substances. In addition, the by-products of the whole process are more useable than the regular process.

As we all know, the metal Li is the lifeblood of the electric car industry. It is reported that an average of 8 kg (17.63 lbs) of Li is required for each car to make batteries. China is currently the leader in the field of Li refining, owning more than half of the world’s production capacity. Tesla has cooperated with Ganfeng Lithium for a long time before.

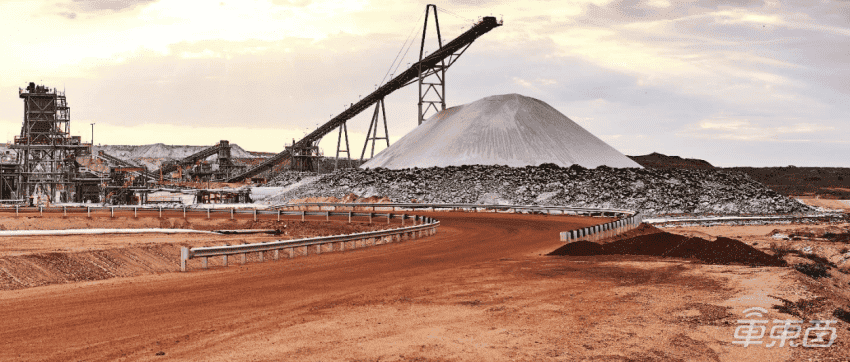

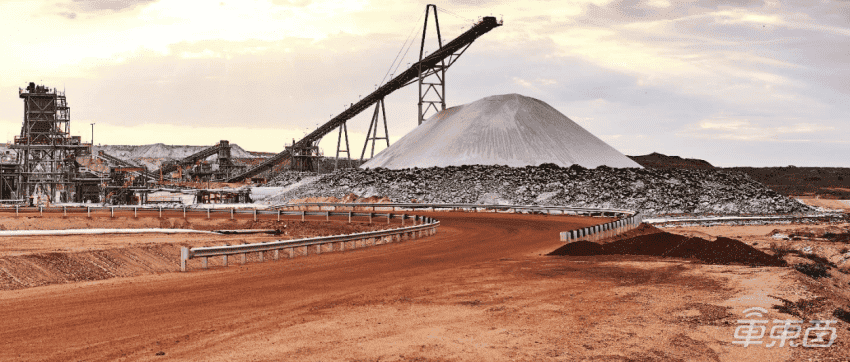

Last spring, Tesla signed two important contracts with Core and Liontown Resources. This is an Australian Li mining company, to purchase spodumene concentrates produced by the two companies. Specifically, starting in 2024, Tesla will buy 100,000 dry metric tons (DMT) of Li concentrate from Liontown Resources in the first year. It will increase to 150,000 dry metric tons per year in other years. Up to 110,000 tons of spodumene concentrate will be supplied to Tesla within four years. The first production of spodumene concentrates is expected to begin in the fourth quarter of 2022 and supply to Tesla to begin in the second half of 2023.

Tesla is serious about the Li plant

A few months ago, sometime last year, there were some papers that shows that Tesla is targeting Texas for its Li plant. Now, the project is on its way and it will build a battery-grade Li hydroxide refining facility. Tesla claims it will be “the first of its kind in North America”. At the moment, the company has permission from the Texas Comptroller’s Office for tax relief. The Li hydroxide produced would be transported by truck and rail to Tesla’s various battery plants to support its large-scale production. The Li refinery will support the production of electric car battery plants.

Tesla lithium refinery will start operation in 2024

In April last year, Elon Musk tweet reads… “Lithium prices have reached unbelievable levels!. Tesla may actually have to go directly into (lithium) mining and mining on a large scale unless we improve our costs. Lithium itself is not in short supply because it is almost everywhere on earth, but extraction/refining is slow”. It is worth noting that recently, Tesla supplier Piedmont Lithium, a well-known US lithium mine company, issued a warning that the US “doesn’t have enough” lithium to achieve electric vehicle goals. China is currently the dominant player in the field of lithium refining. At the moment, China has more than half of the world’s production capacity.

Li prices have been rising

In May last year, the price of spodumene auctioned by Pilbara was $5,955 / ton. This created a new price at that time. According to the insiders at the time, the profit of Li salt was about $7,600 /ton. In June last year, Pilbara said it conducted an auction of Li concentrate and the transaction price was $6,350. This is a 6.6% increase from the last price and a new high again. After adjusting the Li content and freight proportionally, the auction price of this Li concentrate can reach $7,017/ton. According to the current Li market, the profit after the auction of Li ore processed into Li salt is only about $2,800 / ton. This is a strong decline relative to the last auction.

Although the profits of auctioneers have fallen, Pilbara is not planning to stop, and a new round of auctions was launched in July last year. “Contrary to recent market claims that lithium prices have peaked, the company’s pricing results with customers indicate that demand for lithium remains very strong, with prospects for the foreseeable future,” CEO Dale Henderson said in the announcement. Continued optimism.”