Samsung is currently testing Android 14 with One UI 6.0 internally. They have promised a substantial photographic improvement for this spring. It will bring us closer to the 2x ‘zoom’ (50 mm focal length) that many people have been asking for. This improvement will complete what is already considered to be a nearly perfect smartphone by many experts.

Counterpoint Research has recently published a study that reveals the cost of manufacturing a Samsung Galaxy S23 Ultra. The study only focuses on the components and does not include additional costs such as logistics, storage, or tariffs.

The Cost of Manufacturing a Samsung Galaxy S23 Ultra: A Detailed Breakdown

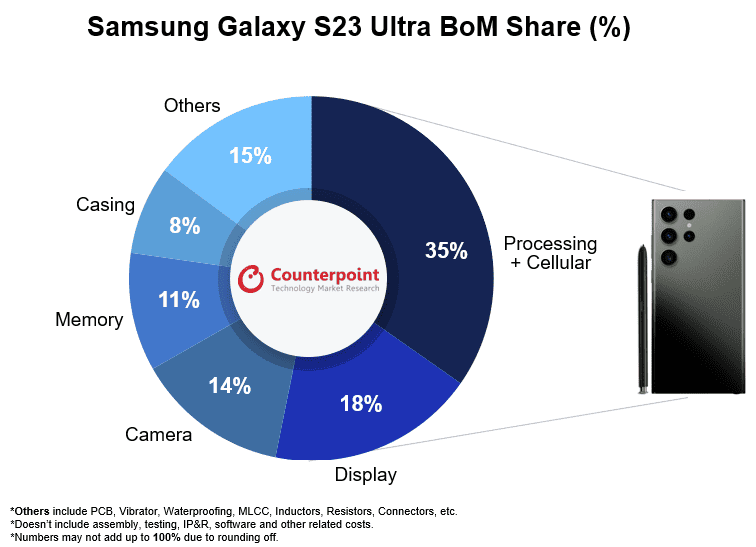

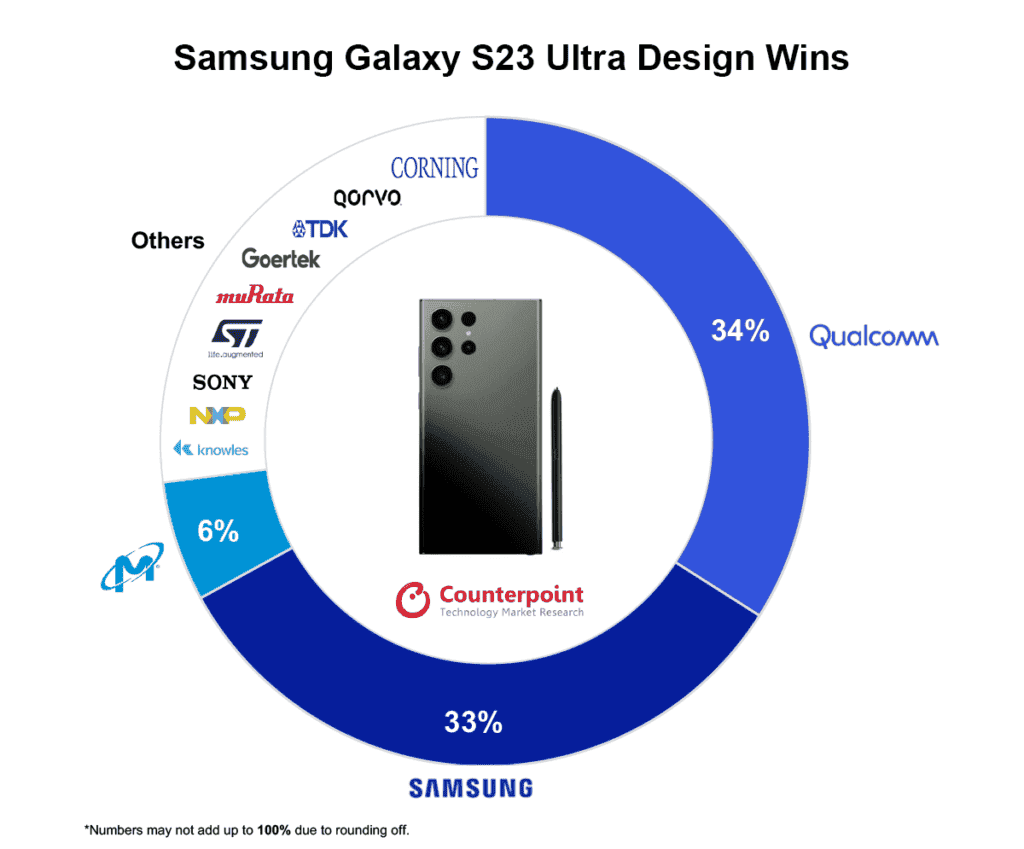

According to Counterpoint’s expert consultants, the manufacturing cost of a Samsung Galaxy S23 Ultra is approximately $469. And 35% of this cost is attributed to the Qualcomm Snapdragon 8 Gen 2 for Galaxy chip. Samsung enjoys it exclusively along with its Snapdragon X70 modem with 5G connectivity. This price includes not only the chipset, but also the 6.8 inch 120 hertz AMOLED QHD+ panel, the memory configuration (RAM + storage), the camera system with its 200 megapixel sensor and its periscopic telephoto lens, as well as the speakers, the S-Pen, and a long list of components.

It is interesting to note that the screen is the second most expensive component. It’s originating from Samsung and with Dynamic AMOLED 2X technology. It’s representing 18% of the entire final component bill. The camera system represents only 14% of the price of the Galaxy S23 Ultra.

Memory accounts for 11% of the cost, while case and chassis materials take 8%. The remaining 15% is for everything else, such as connectors, keypads, S-Pen, speakers, microphones, and most importantly, the battery.

Comparing the component price of flagship phones from Apple and Samsung. It seems that manufacturing an iPhone 14 Pro Max and a Galaxy S23 Ultra cost about the same. However, the profit margin that Apple allows itself is much higher than Samsung’s.