The iPhone 15 series is one of the most anticipated mobile phone releases of the year. With rumors and leaks circulating online, many are excited to see what Apple has in store for its latest flagship device. One of the most talked – about issues regarding the iPhone 15 series is the production capacity of its CMOS sensors.

What is CMOS?

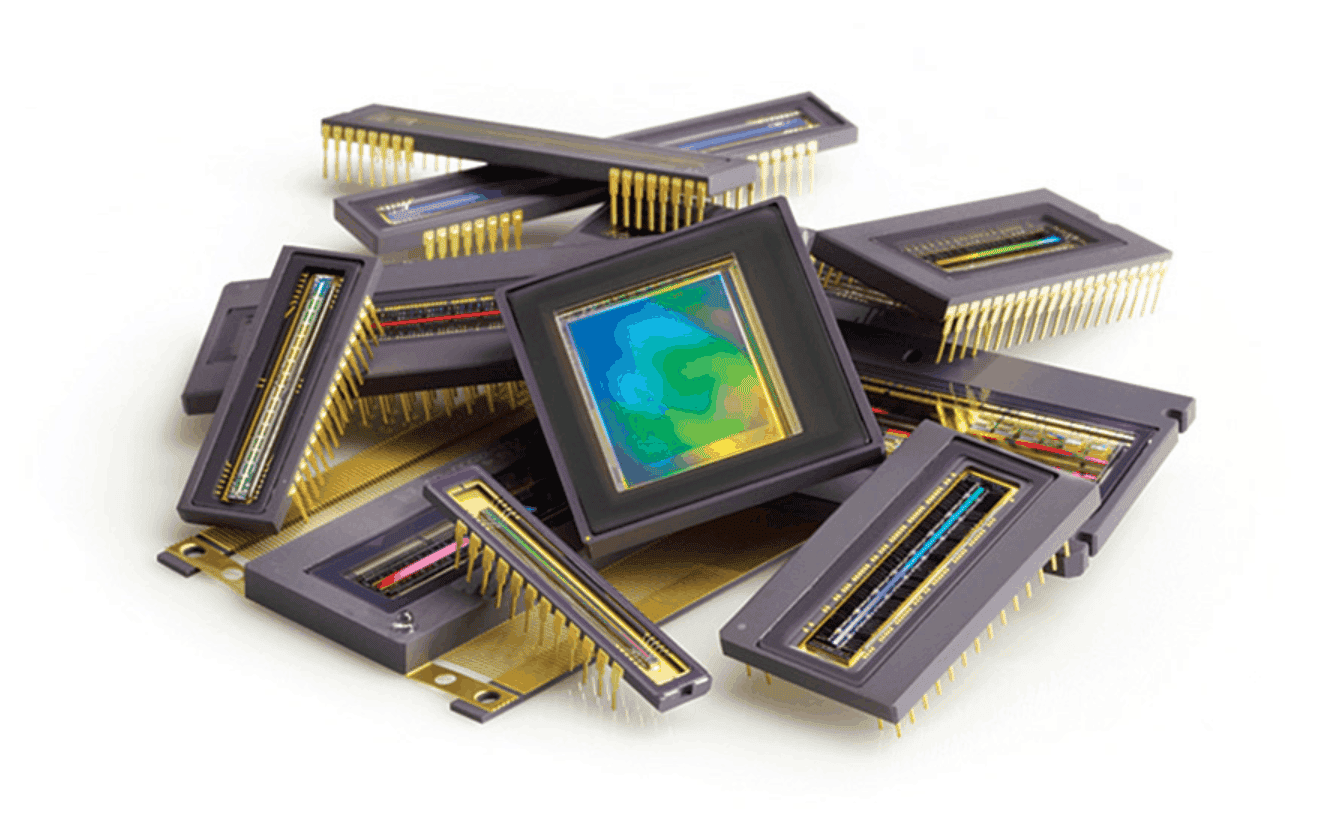

Before we dive into the specifics of iPhone 15 series CMOS production capacity, let’s first define what CMOS is. CMOS stands for Complementary Metal-Oxide-Semiconductor. This is a type of image sensor used in digital cameras and mobile phones. CMOS sensors are known for their low power consumption, high – speed data transfer as well as excellent image quality.

The iPhone 15 Series CMOS Production Capacity

According to recent reports, the production capacity of the iPhone 15 series CMOS sensors is very low. MacRumors claims that the reason is due to the fact that Apple is planning to use a new 3nm process for its A17 chip. This chip is expected to be the first A-series chip built on a 3nm process. The shift to a newer process will result in smaller chip sizes because of increased transistor density. However, the 3nm chips cost much more money. This has led to a shortage of production capacity for the iPhone 15 series CMOS sensors.

Sony takes action

Sony is in charge of the iPhone 15 series CMOS sensors and the company is taking relevant steps to curb the issue. There are reports that Sony had to expand its order for colour filter films from TSMC. This is in an attempt to tackle the low production capacity in the back end of its own image sensors.

Sony’s latest mobile phone sensor adopts stacking tech, and its structure also upgrades from the previous two layers to three layers. The latter is more complex and needs a high – end production process. Most of Sony’s latest mobile phone CMOS sensors use stacked tech, which stacks photodiodes and amplifier circuits in structure. The advantage is that it can boost the sensitivity to light, signal – to – noise ratio, and greatly reduce image noise.

IT Home claims that Sony will adopt a “dual – track parallel” strategy. While it focuses on expanding the front – end production capacity, it is expected to expand cooperation with TSMC.

Potential Impact on iPhone 15 Series Performance

The low production capacity of the iPhone 15 series CMOS sensors could potentially impact the device’s performance. CMOS sensors are a critical component of a mobile phone’s camera system. Thus, the shortage of production capacity could lead to delays in the device’s release or a decrease in the number of devices available at launch. Also, the shortage could lead to an increase in the price of the iPhone 15 series. This is because Apple may need to pay more to secure the necessary parts.

According to the supply chain, since the new generation of the iPhone 15 series will fully upgrade to a 48MP main camera lens, compared with the current high-end models such as the iPhone 14 Pro / iPhone 14 Pro Max, its demand will naturally increase. Coupled with the increase in sensor size, Sony’s own production capacity is tight. Therefore, after Sony handed over the pixel layer order to TSMC for the first time last year, it is interested in further expanding the back-end process to peripheral suppliers this year.

Final Words

The production capacity of the iPhone 15 series CMOS sensors is low due to the shift to a new 3nm process for the A17 chip. This shortage could potentially impact the device’s performance and lead to delays in the device’s release or an increase in its price. However, it is important to note that Apple has not yet confirmed these reports. We will wait for the official release of the iPhone 15 series to see how this issue will be resolved.