We already know the UMIDIGI C Note shares the same design of their flagships UMi Z and Z Pro but at the same times it sports less performing hardware to make it much cheaper than them. That doesn’t mean it has been made with less attention to the details, though, and that’s why the Chinese phone maker decided to share with us why and how they created the C Note.

From past articles we learned the UMIDIGI has been created from a single slab of aerospace-grade aluminum which then goes through 48 hours of CNC machining to reach its final look. Today, we have UMIDIGI’s founder himself — Heaven — explaining us every step of the process.

Before jumping into the details, this is what UMIDIGI had to say about its leitmotif:

Forging the metal into shape

That may sound obvious but yes, forging metal into a shape isn’t as easy as it sounds. Holes are first punched into the body, then pressed and cut, to hold the steel plate in place during subsequent processing steps. Followed by 100-tonne hydraulic forging press that gives the C Note its basic silhouette. Additional measures such as annealing are applied to further harder the steel.

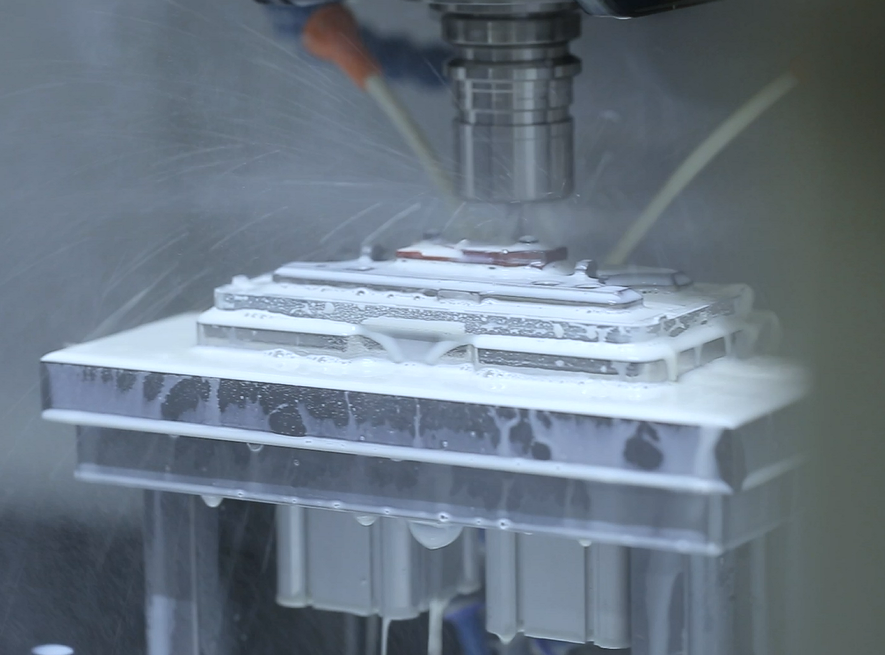

Completely CNC processed

UMIDIGI uses CNC machining to give the C Note its final shape. That consists of about 58 milling operations in 8 steps. The volume and power key holes are created by a natural diamond ball cutter, instead the speaker and sd card slot are made with a 4-axis CNC machine tool which can perform 360-degree rotations and has a precision of 0.01mm. This process does cost more but it gives far better results, creating more neat and clean openings.

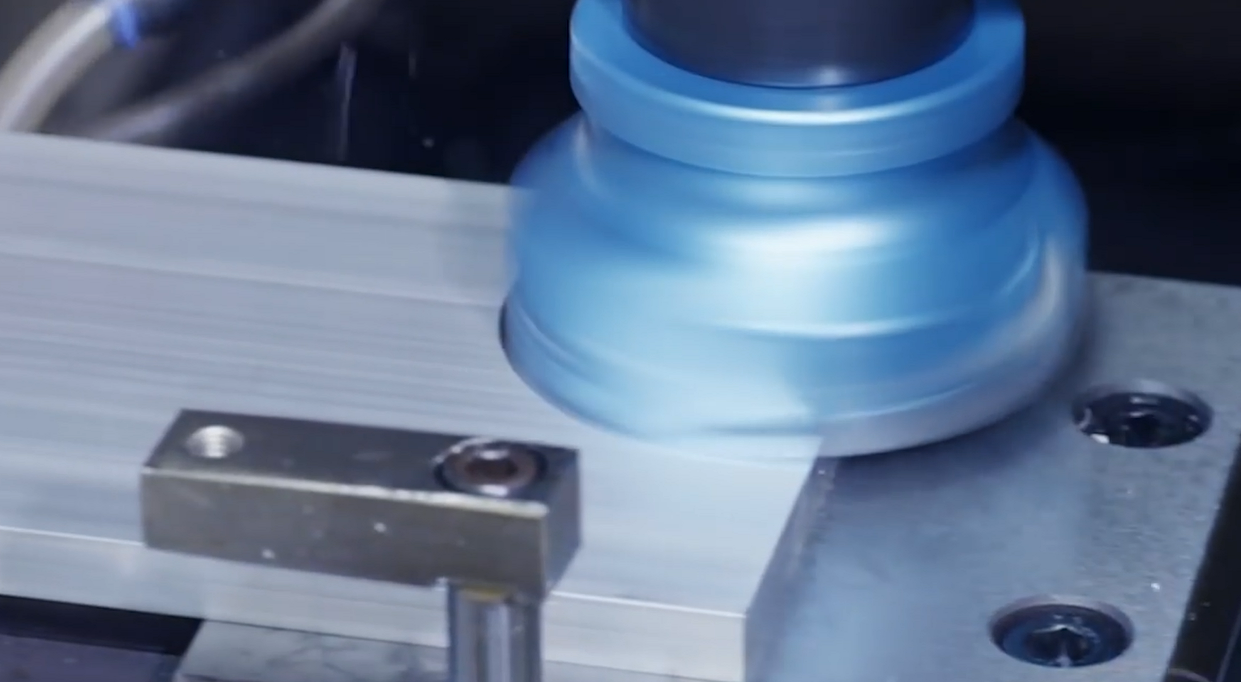

3 Steps surface polishing

So the C Note has its final shape at this point but you wouldn’t really like holding one yet. Surface polishing is really important and the C Note gets 100 seconds of rough polishing to remove residues from the milling machines. It then gets a wet medium polish to smooth it even more, finally it receives a mirror polish which gives the curved parts a slick look.

Gizchina News of the week

Ultra smoothness from ultra-fine sandblasting

To give the UMIDIGI C Note an even better feeling in the hands, the phone manufacturer also puts the handset through a fine-tuned sandblasting process. The chamfered edges are polished with oil ink before the process, the frame sides are also buffed to reduce surface roughness. Compressed air sandblasters will then give a silky smooth finish to the back and the sides.

Laser cutting frame completion

As we’re getting closer to the end, an highly focused laser beam vaporizes stainless in seconds, cleanly separating the frame from the needless metal. UMIDIGI technicians then polish the frame to remove all the burrs and residues in the cut-off areas. Before completion, the frame gets inspected at least 3 times to ensure the quality of the job.

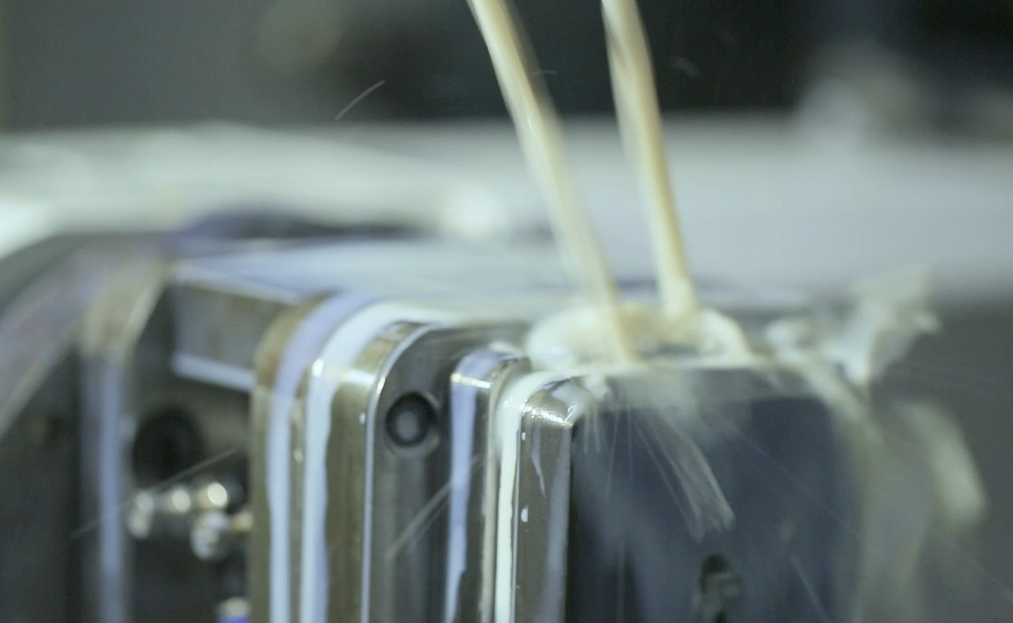

Edge Coating for screen protection

Finally, a 0.05mm-thick layer is added under the glass with a special “Edge Coating” that acts as a shock absorber if the phone gets accidentally dropped, reducing the chances of the screen shattering.

“A Via Negativa Journey”

And that’s how UMIDIGI made the C Note. Did you guys find it interesting? Let us know in the comments below!