According to reports, in order to minimize the risk of the COVID-19, TSMC has adopted a series of new measures, including reducing face-to-face contact between operating teams and prohibiting non-core suppliers from entering TSMC’s factories. In a statement, TSMC said that its employees and suppliers must avoid moving between factories and offices in Hsinchu, Taichung, and Tainan. It is adopting this operation style to reduce the flow of personnel across factories. All employees, suppliers, and contractors should follow the “independent team” work model.

In addition, TSMC also restricts “face-to-face” meetings and prioritizes remote connections; if it is unavoidable, only necessary personnel can participate, and a social distance of 1 meter is maintained. Recently, the coronavirus situation in Taiwan, China continues to increase. In addition to TSMC, MediaTek and Hon Hai Group have all taken similar measures.

Hon Hai Group launched the new ten major epidemic prevention measures last Friday. This includes the implementation of hierarchical distribution and grid management of floors. All meetings have to be on a video chat and it bans gathering of more than five people.

MediaTek announced yesterday that employees working in Taipei and their main residence in the Shuangbei area will all work from home; employees in the Hsinchu area will adopt hierarchical and diversion measures to protect the safety of employees.

The U.S is slowly becoming a battlefield for chip manufacturers

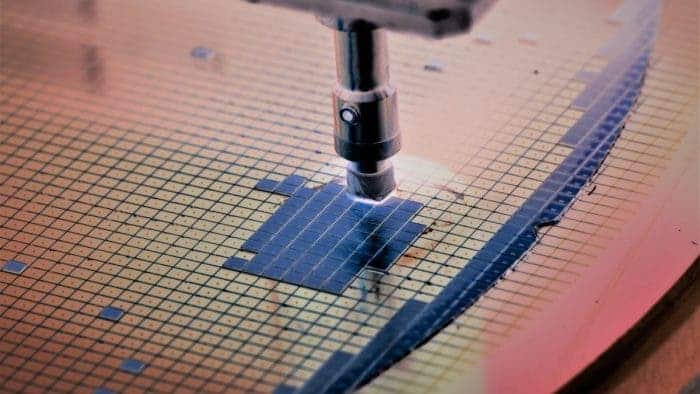

There are reports that TSMC will set up new 5nm chip plants in the U.S. According to the reports, the company will build six 5nm process chip factories in Arizona. In addition, Samsung is also planning to invest in a 3nm chip factory in Texas, USA. Furthermore, Intel also announced that it will invest $20 billion to build two wafer fabs in Arizona, USA. If these reports materialize, then the U.S. will become a new battleground for the major players in the chip industry.

TSMC is currently deciding whether to a more advanced 3nm process for its next plant in Arizona. If the company decides to use the plant for 3nm chips, then the factory building cost will be between $23 billion and $25 billion. However, if it decides to use it for a less advanced process, it will spend lesser.

An insider said that

“Because the (TSMC) Phoenix, Arizona plant will be expanded in the next 10 to 15 years, TSMC’s management has also drafted a plan to produce 2nm and more advanced process chips in Phoenix.”.According to TSMC’s CEO, Wei Zhejia, TSMC’s “further expansion is possible” in Arizona.

Follow Gizchina.com on Google News for news and updates in the technology sector.